Dupont

Enno Jacobsen, director

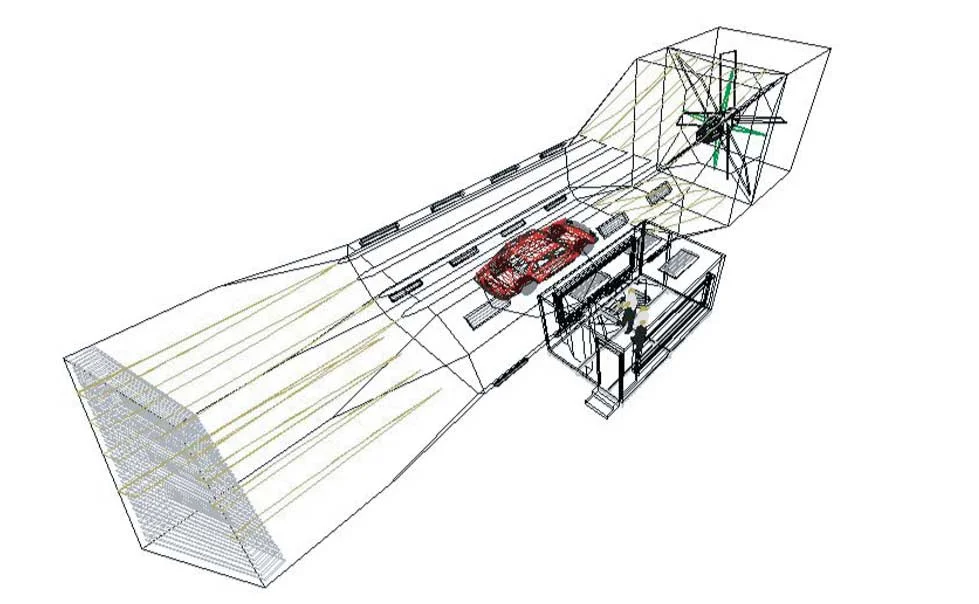

Brief: Scientific Wind Tunnel Test Facility. We wanted it to look as though it received regular use, and had been around for decades, nothing too high tech or flashy - we didn’t want to distract from the car or the car care products.

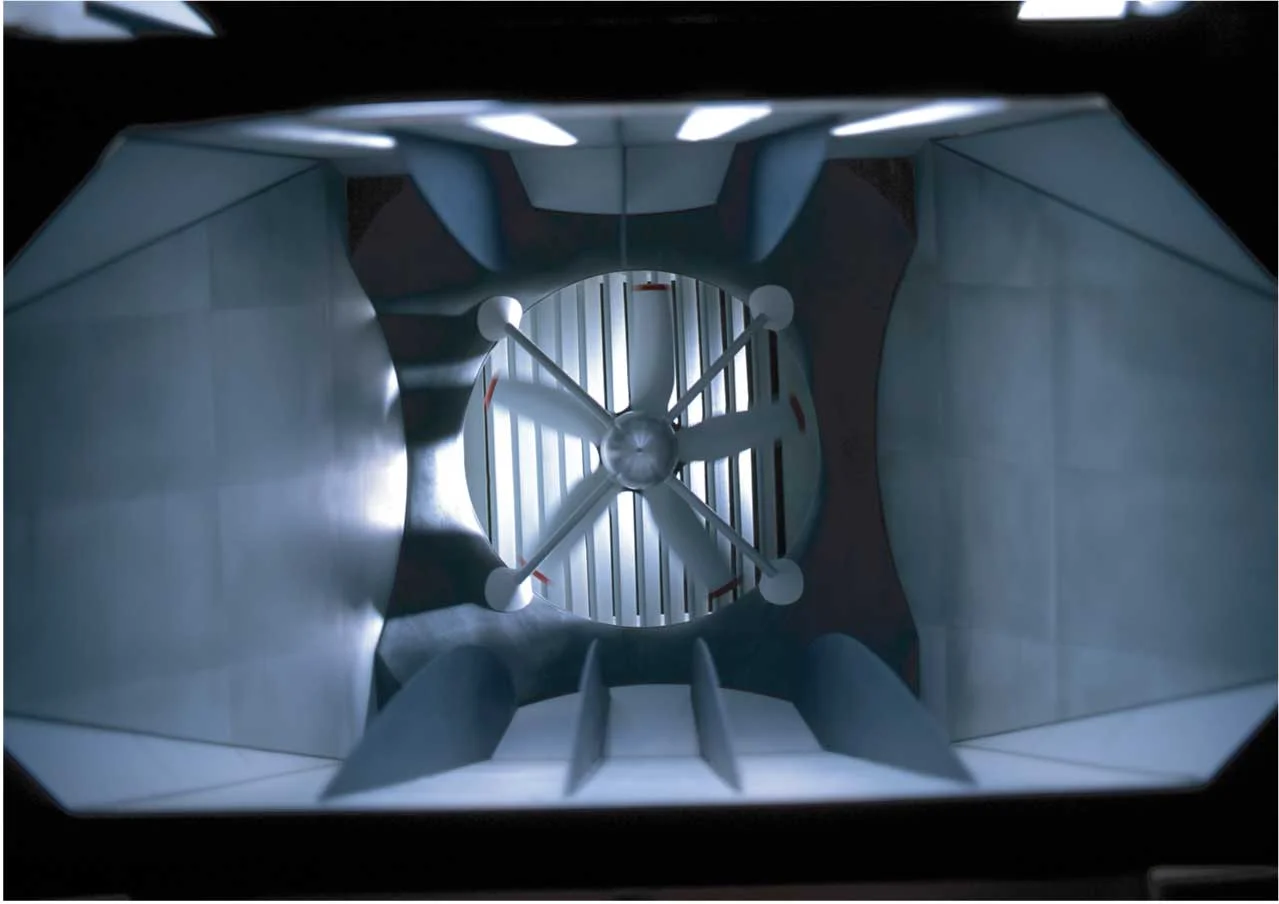

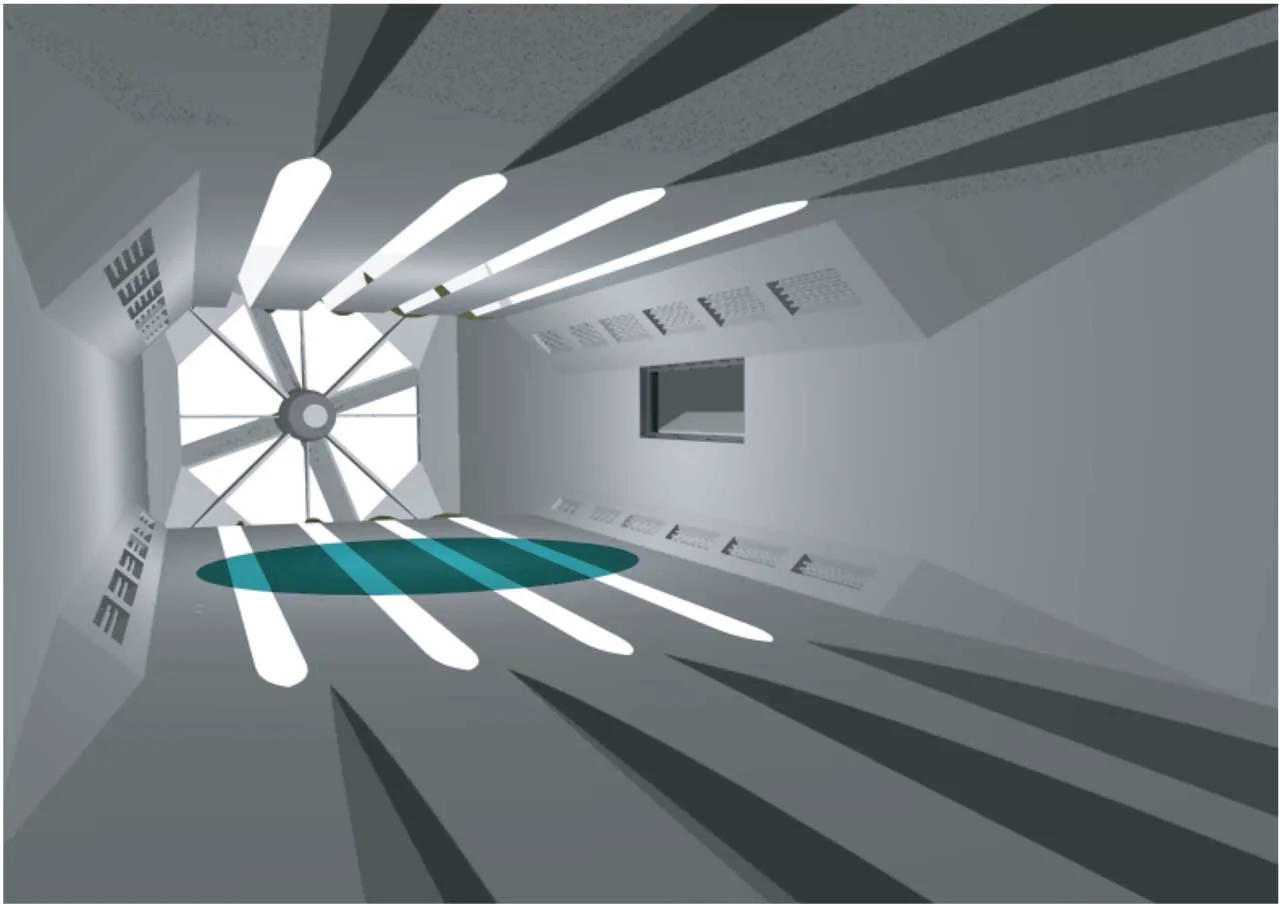

1,2) In the story, the researchers are testing the new Dupont Teflon Car Care Product line, after application, they subject the car to a bucket of mud under driving (wind) conditions. The result is a sparkling clean car and a mud covered technician. Here the technicians prepare for the test. In the control room to the left are the test supervisors from Dupont. Beyond them, through the back window is the wind tunnel circuit return wall.

3) Interior of the control room where the two supervising Dupont technicians were managing the instruments and controlling the tunnel wind generating fan. It is from here that they observe the performance of their products with satisfaction as the car sheds all of the mud - much to the demise of the lowly tunnel tech.

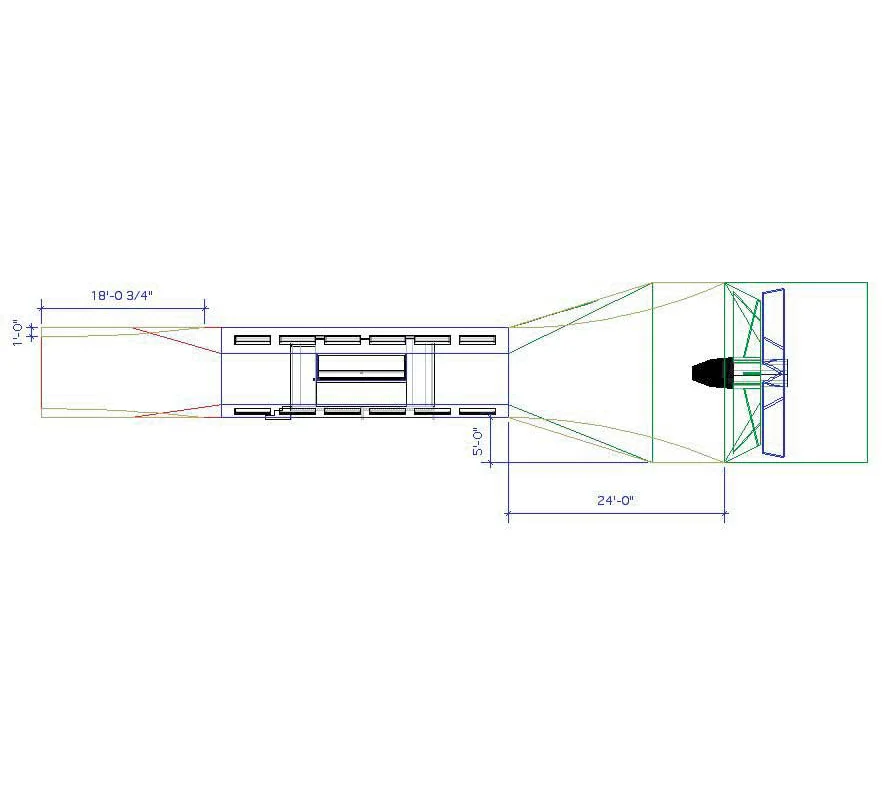

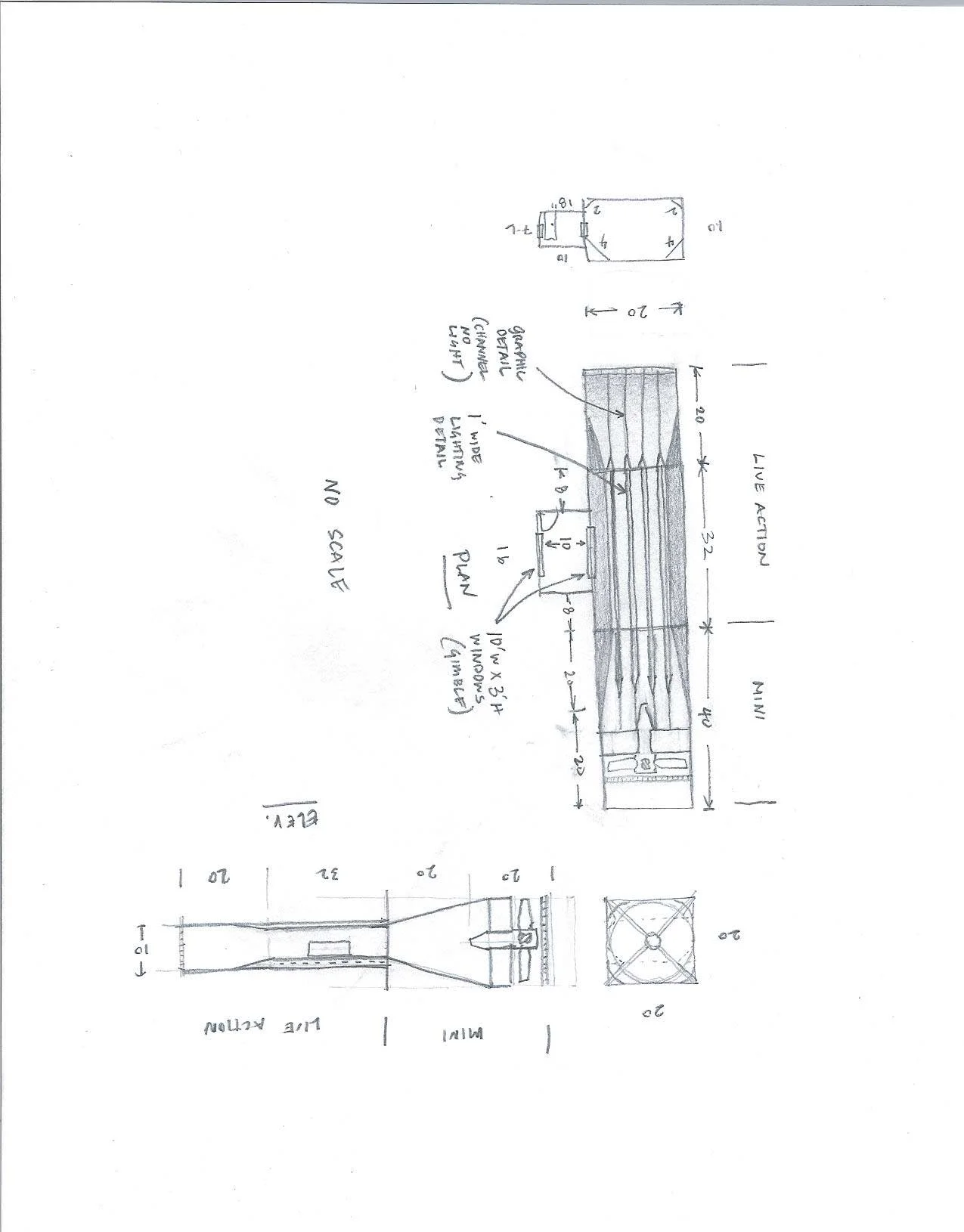

4) This is the miniature of the Wind Generating

Fan. We had to resolve many financial challenges on this project, and en lieu of building a full scale elevated set with a 20’ diameter operating fan, I proposed we build a miniature and do simple composition shots to give our facility scale... this proved to be very successful in satisfying our quest for realism and massive scale.

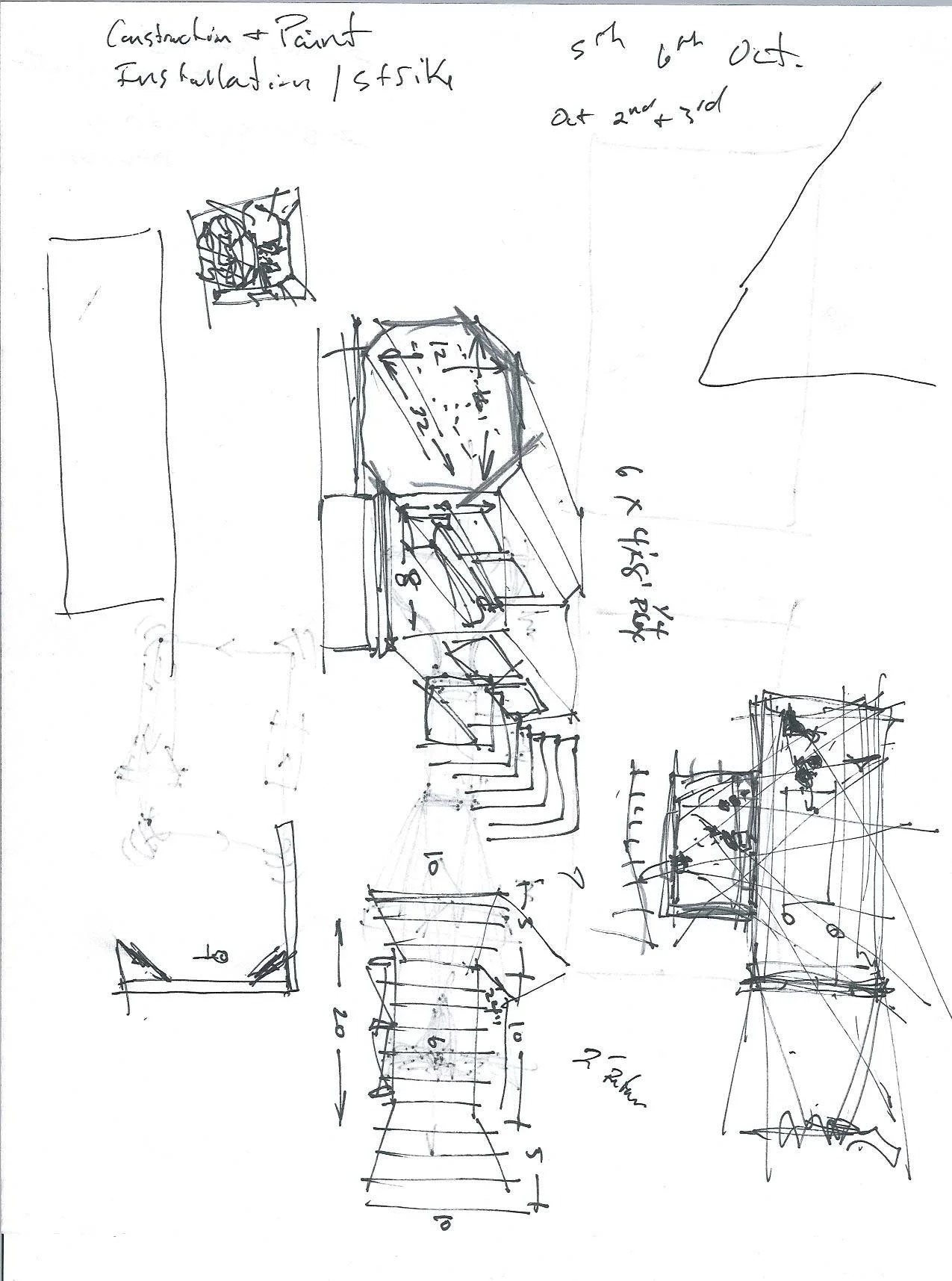

5,6) Drafting the set in the computer allows for a

more exacting match in post production composition work, as well as providing an opportunity to pre-visualize expected shots, allowing the creative team to answer questions before a single staple is fired into wood. Additionally, drafting in the computer is typically faster and more efficient.