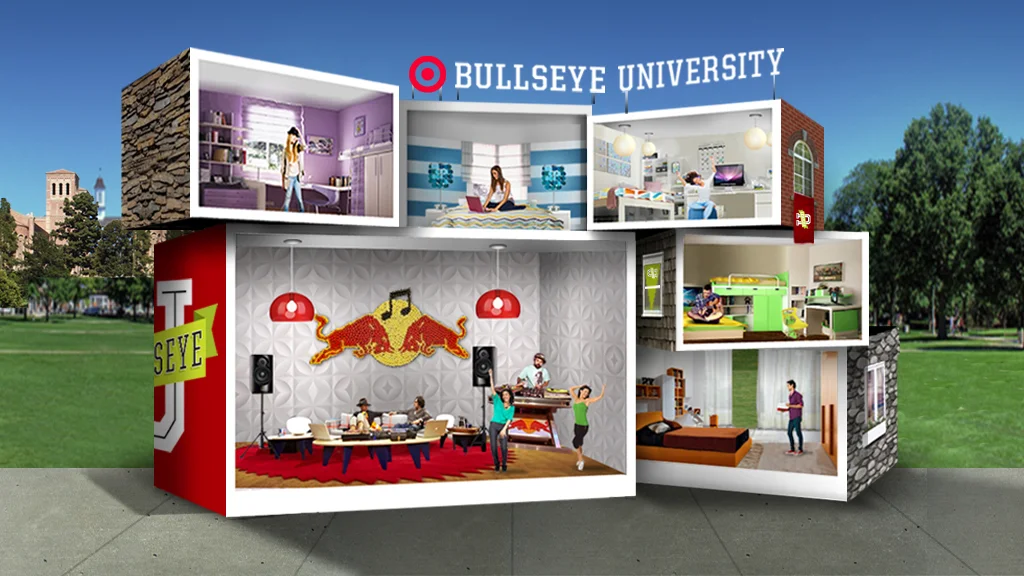

Here is a project that was never meant to air on television, but instead, was to be a living catalog transpiring over 4 days, twenty-four hours a day, with events and content for punters to engage over the internet.

HOW TARGET BECAME THE BIG BRAND ON CAMPUS

http://www.eventmarketer.com/article/grand-ex-2014/

The event wound up being incredibly successful with 76 Million Twitter impressions, 152 Million PR impressions across several outlets, and 1.7 Million page views, amounting to “6.8 Years of high-value, purely opt-in time with core audience over 4 days”.

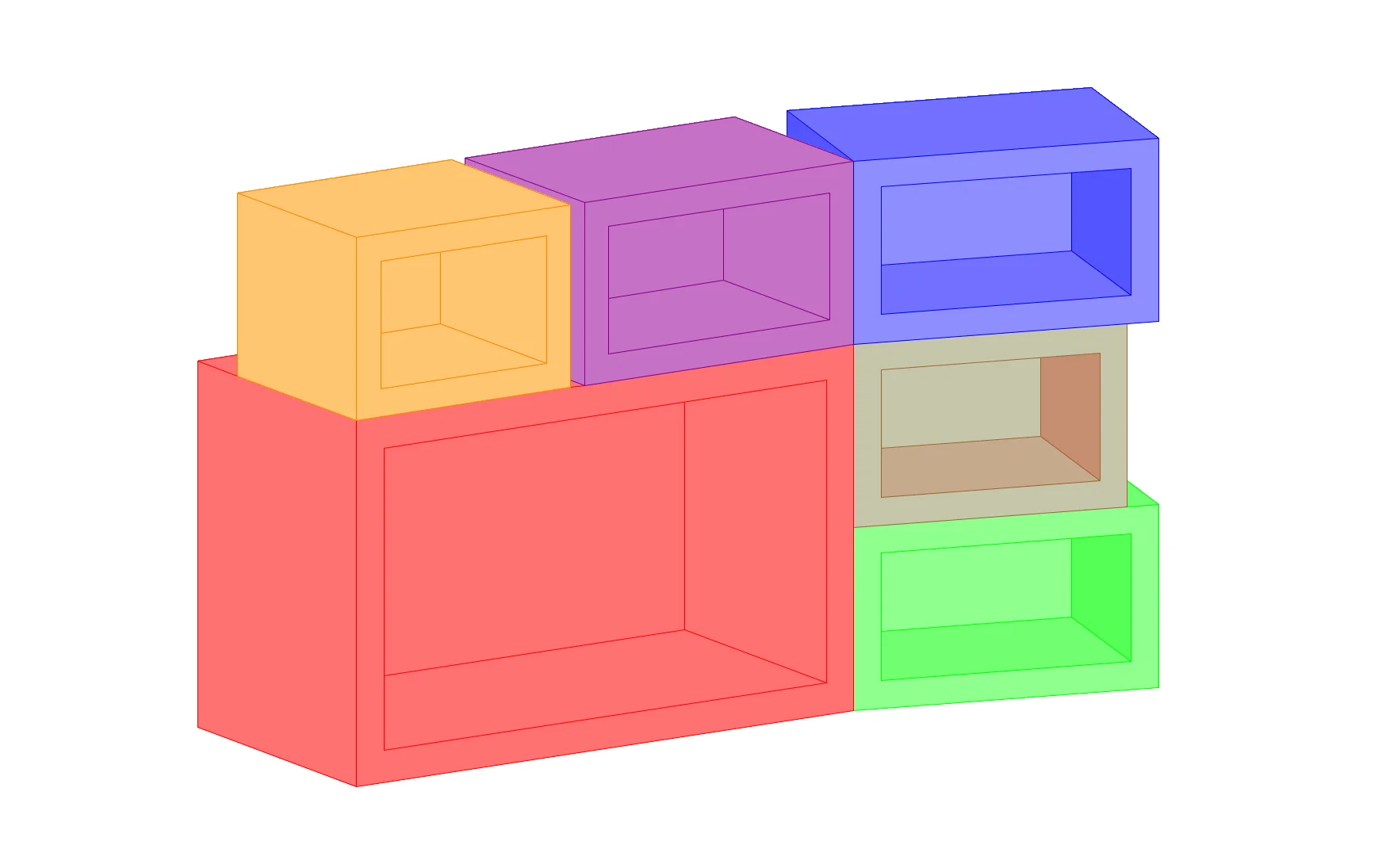

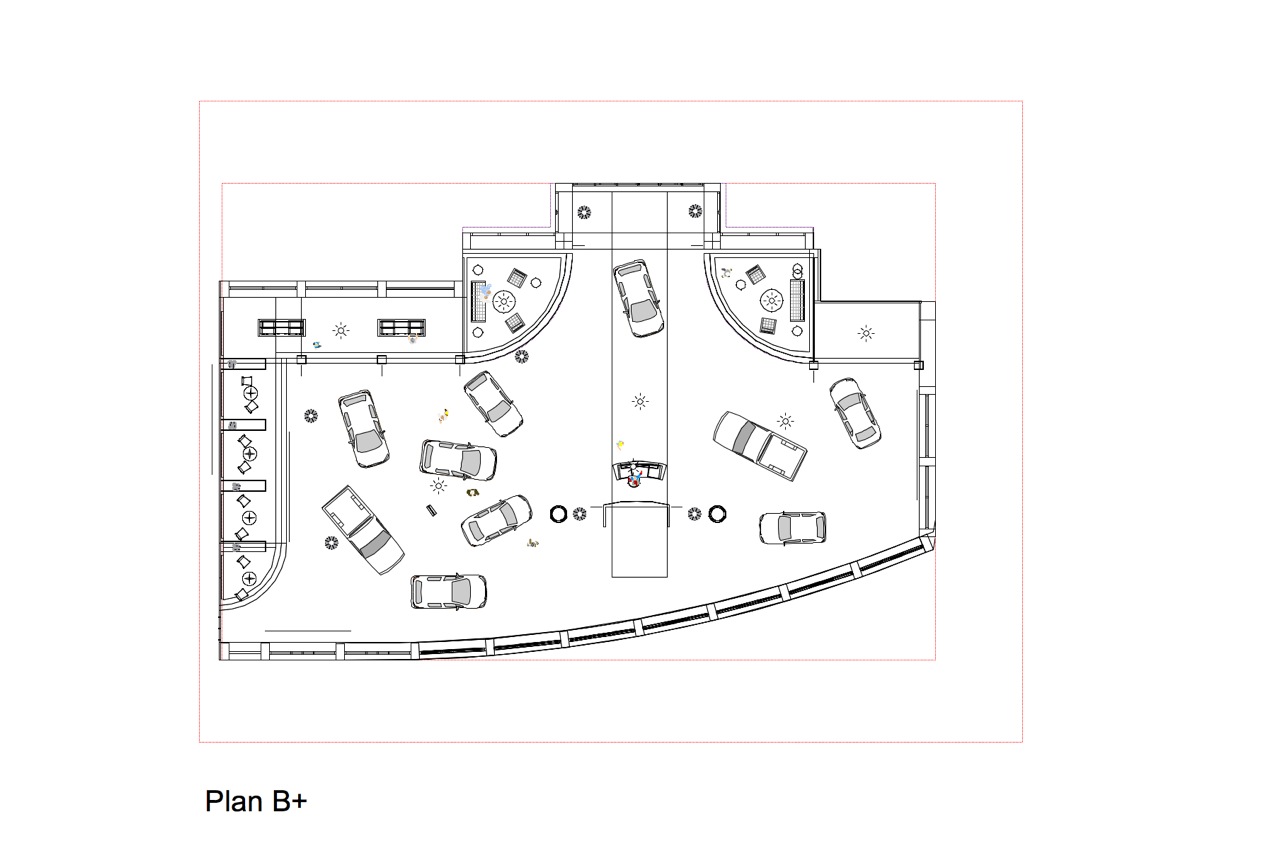

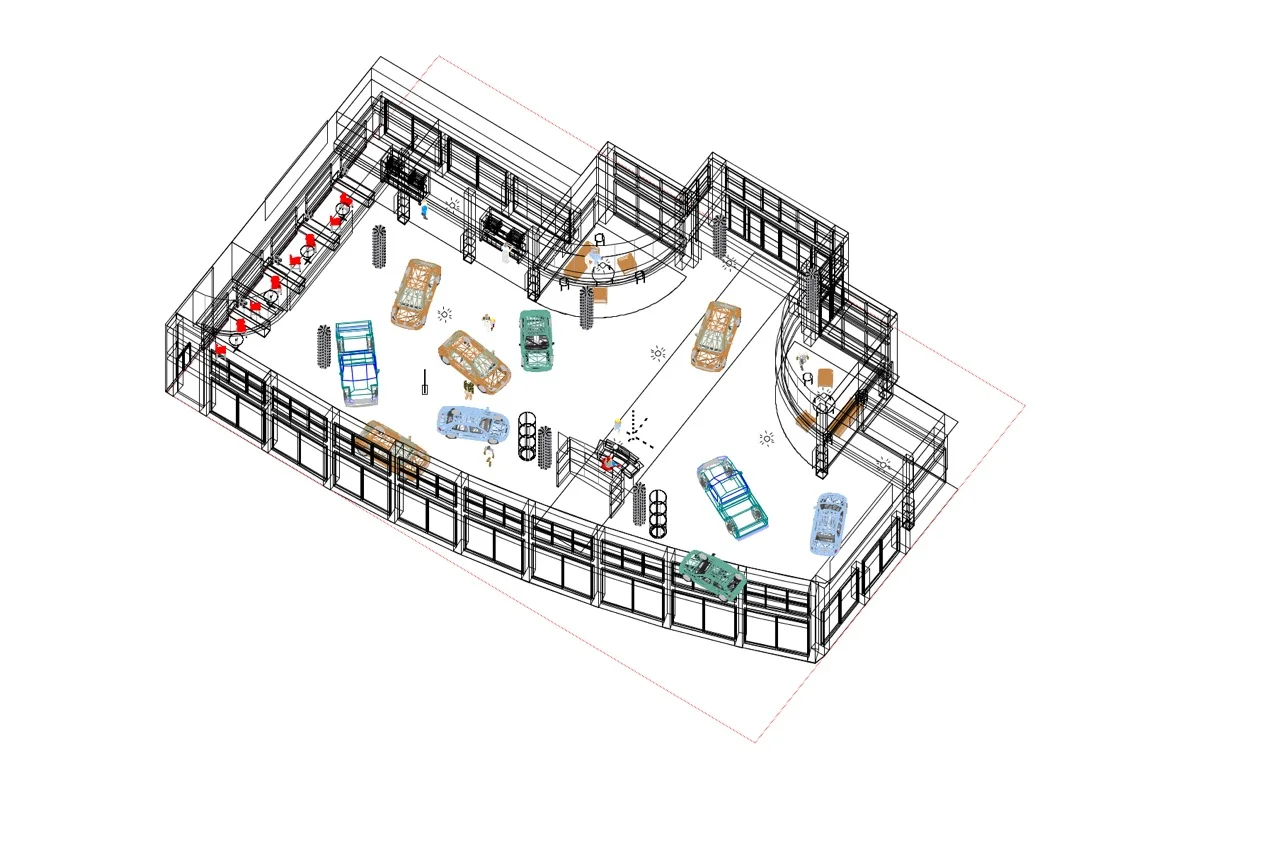

It began as a concept of stacked dorm rooms and a common activity/brand room grouped together in a contained environment where our web-celebrity (dubbed: cewebrity) talent could interact with roommates, or, not celebrity talent that would occupy the dorms through the night.

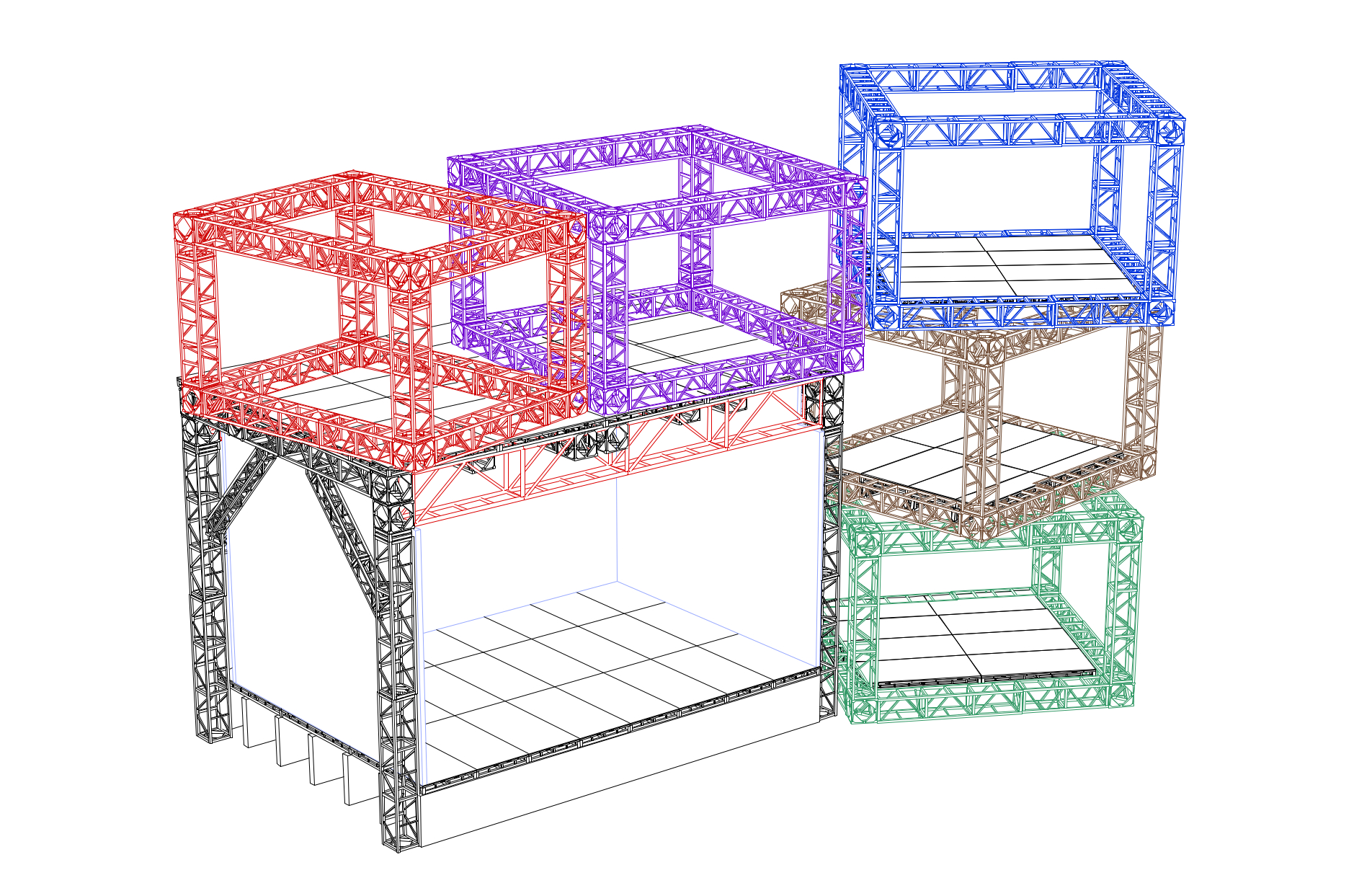

Of course, as a concept this presents some great challenges, all of which I was eager to meet. From creating an aesthetically cool and interesting arrangement of rooms, to the accessibility and safety of crew and talent, and such basic considerations such as having this set sitting in an outdoor parking lot in July for more than a week (including prep and wrap) and assuring the set dressing/Target Product would be safe from sun, wind and rain damage (there were thunderstorms predicted , though they never materialized).

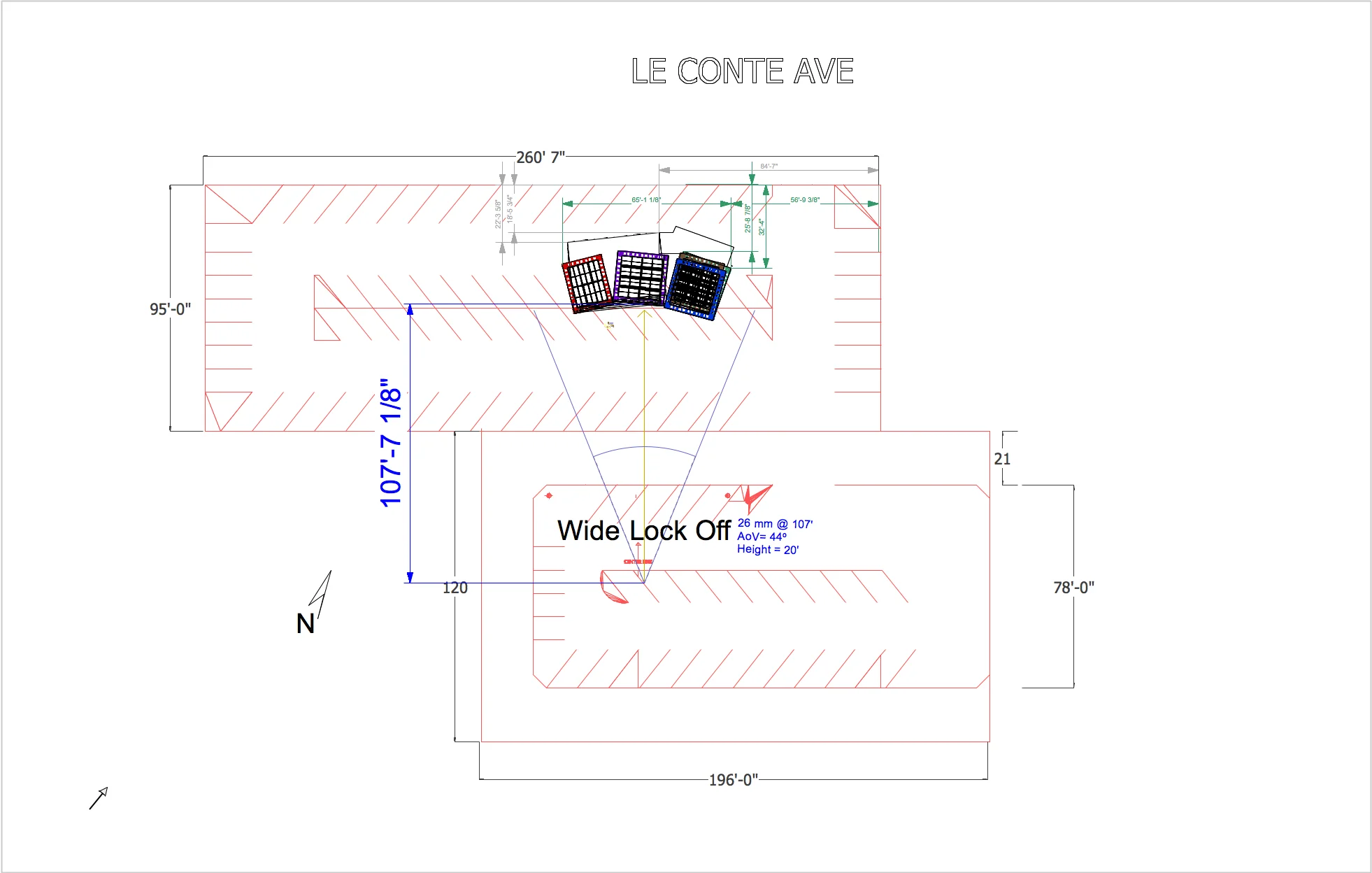

Additionally, we would want to make the assembly and disassembly as efficient as possible to reduce days on location, waste, and risk of injury or accidents. Immediately I knew that building “units” and assembling with a crane was going to be our best advantage in meeting all these challenges, but doing a scratch build proved expensive and time consuming, so logically, I chose to go with modular materials with known dimensions and engineering limits, so we could pre-design/prefab as much as possible before setting foot on location. For this, I reached out to Wes Brown of Hopper Engineering and Mike Krevitt of Showrig, two professionals I have worked with in the past, and knew I could trust to formulate a system that would be safe, efficient and cost effective.

Once I had some of the structural dimensions that would handle our specification, as well as aesthetic demands, I could incorporate them into my design and present a conforming conceptual design and proceed with construction plans for the sets that needed to inhabit the units.

One thing I have not mentioned is that these Dorm Rooms would need to be filmed from the exterior without limiting the view to the interior, or rather, we needed to obliterate the “Fourth Wall” so to speak, while maintaining safety for talent and crew working 3 stories above the parking lot for 24 hours a day, in light and dark. For this we designed a mounting clip that allowed us to use ½” Lexan on the front of each Dorm Room. These clear membranes would provide bulletproof safety, weather protection, and minimal seams to allow unfettered wide shot views into the Dorm Rooms.

Each room was dressed according to the cewebrity character, and showcased Target products that were specifically from the Bullseye University Back-to-School. Since each room was to be LIVE viewed by a single perspective we were able to design the rooms to a specific camera angle in the pre-visualization.

Additionally, we wanted to represent different types of campuses as best we could in the rooms, as if each dorm were “lifted” from a campus and “delivered” here for the event. Though we couldn’t use specific campuses, we used characteristics on the interiors as well as the printed vinyl exterior wraps (used for weather proofing, weight management and efficiency of installation/strike) that we thought were typical of “types” of institutions.

In order to simplify ingress and egress of the set dressing and construction materials, we chose to build the sets, and fill the units with dressing on the ground and then lift them into place with the crane. This also saved time and money, as well as decreasing the risk of accidents or injuries humping big pieces and boxes up narrow stairs that were attached primarily personnel.

Finally, there was the event/brand stage where some of these programs were to take place. Some of the brands partaking in the event were:

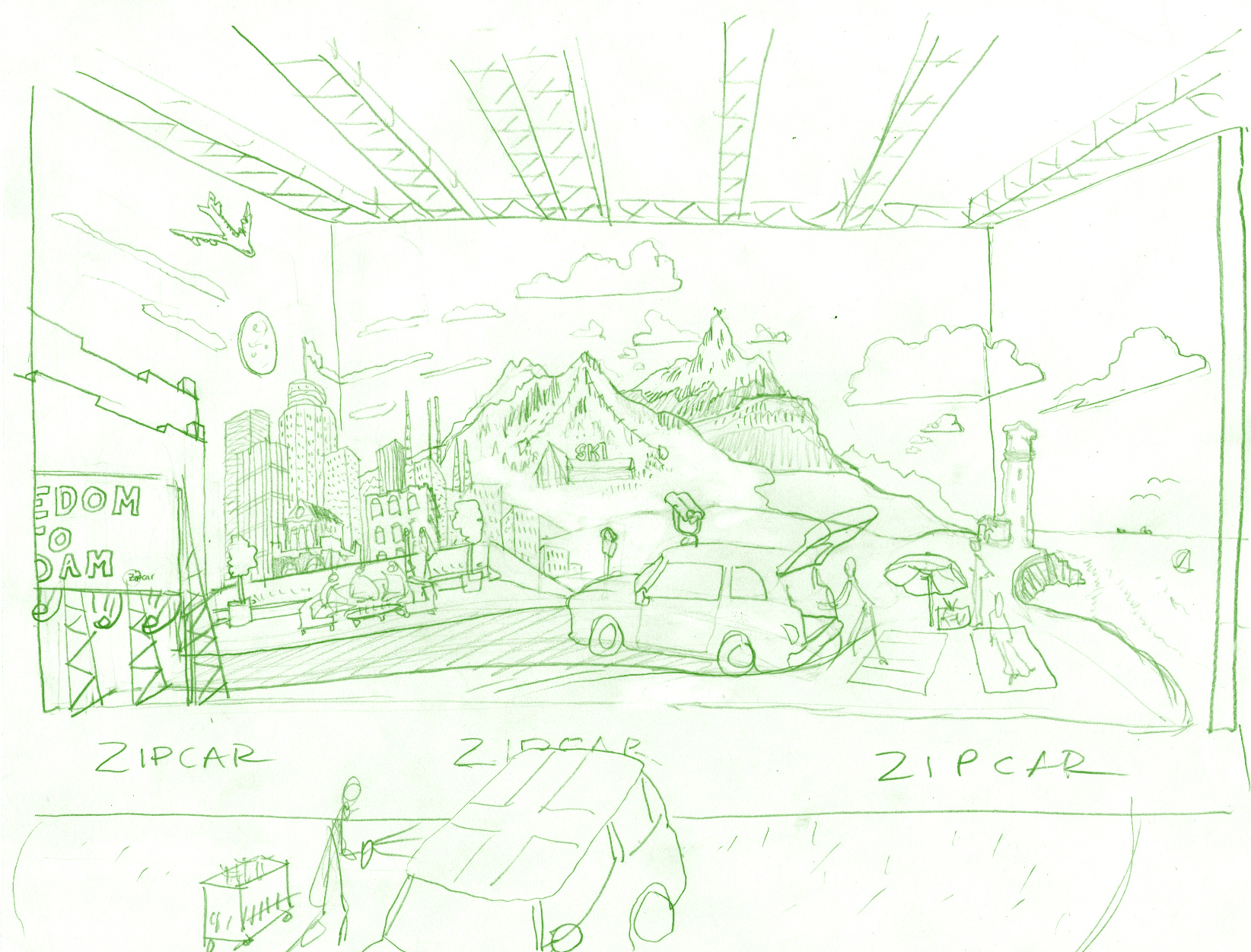

ZipCar – we did 2 game shows: Price That Haul and Fit It!, and a painted Art Car. For the set we went with a great flat art style using seamless paper and cardboard to fabricate the set and make a fantasy abstract world representing the places that may be visited using a ZipCar, and escape the rigors of University life.

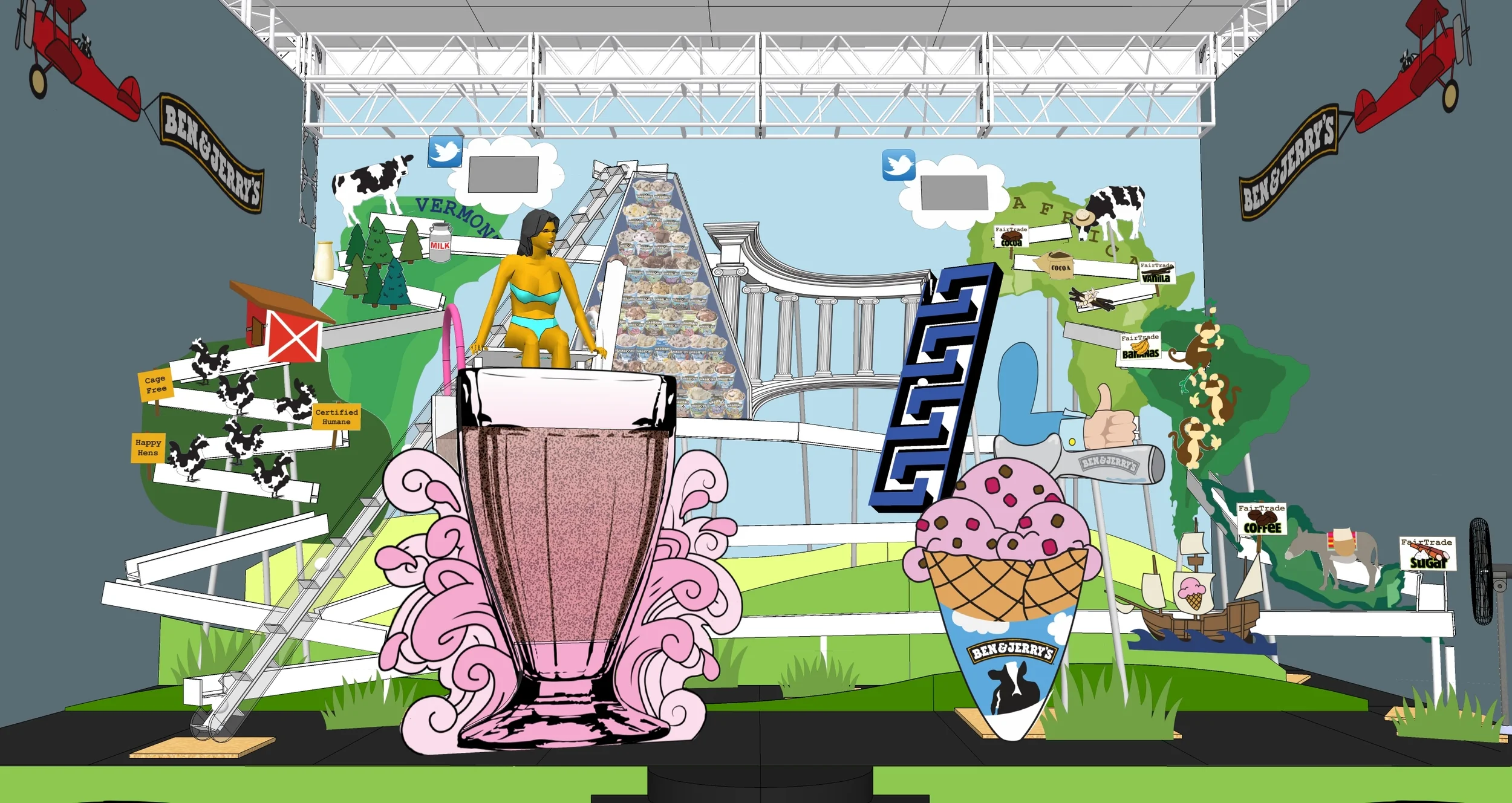

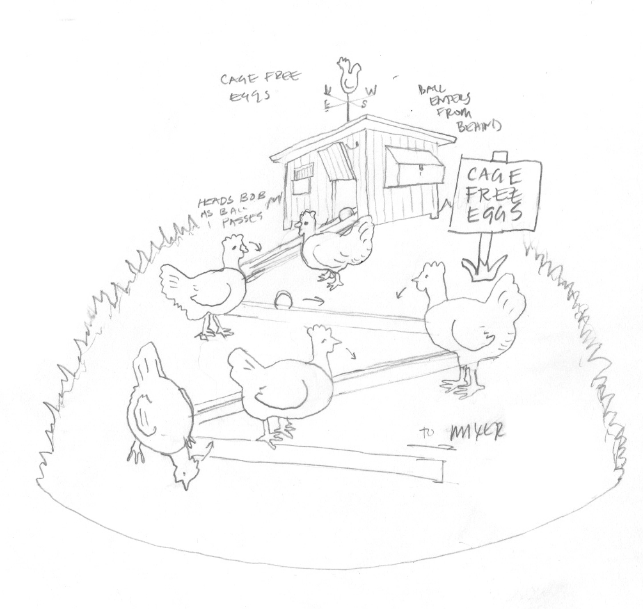

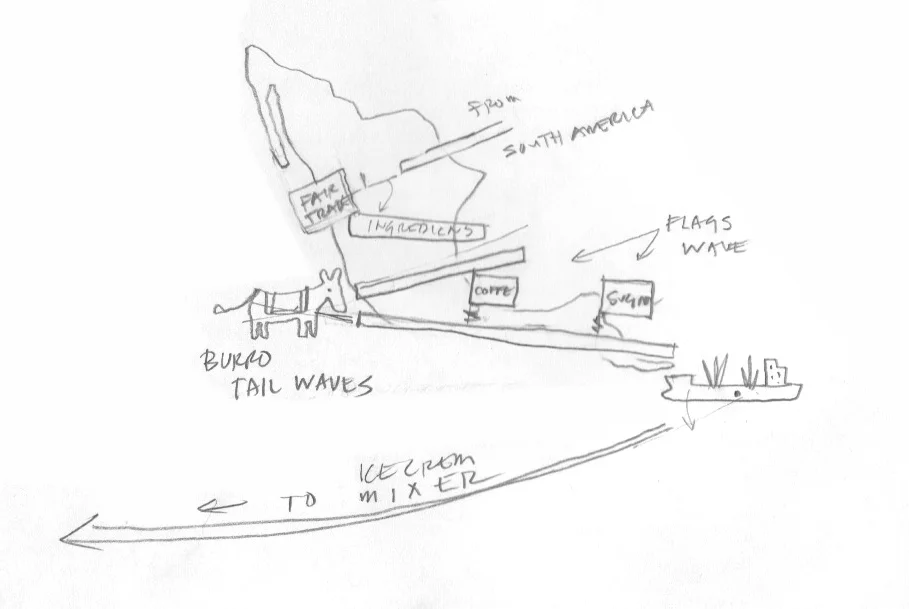

Ben & Jerry’s Ice Cream – we invented and built a Rube Goldberg Kinetic Event Dunk Tank that was powered by Tweets and hosted brand presentations. This installation followed the story of ice cream from “cow to cone” as we followed each tweet from either the dairy side or the flavor side until we had enough scoops (tweets) to dump our talent into the tank filled with strawberry milkshake (methylcellulose minus the sugar and flavor!).

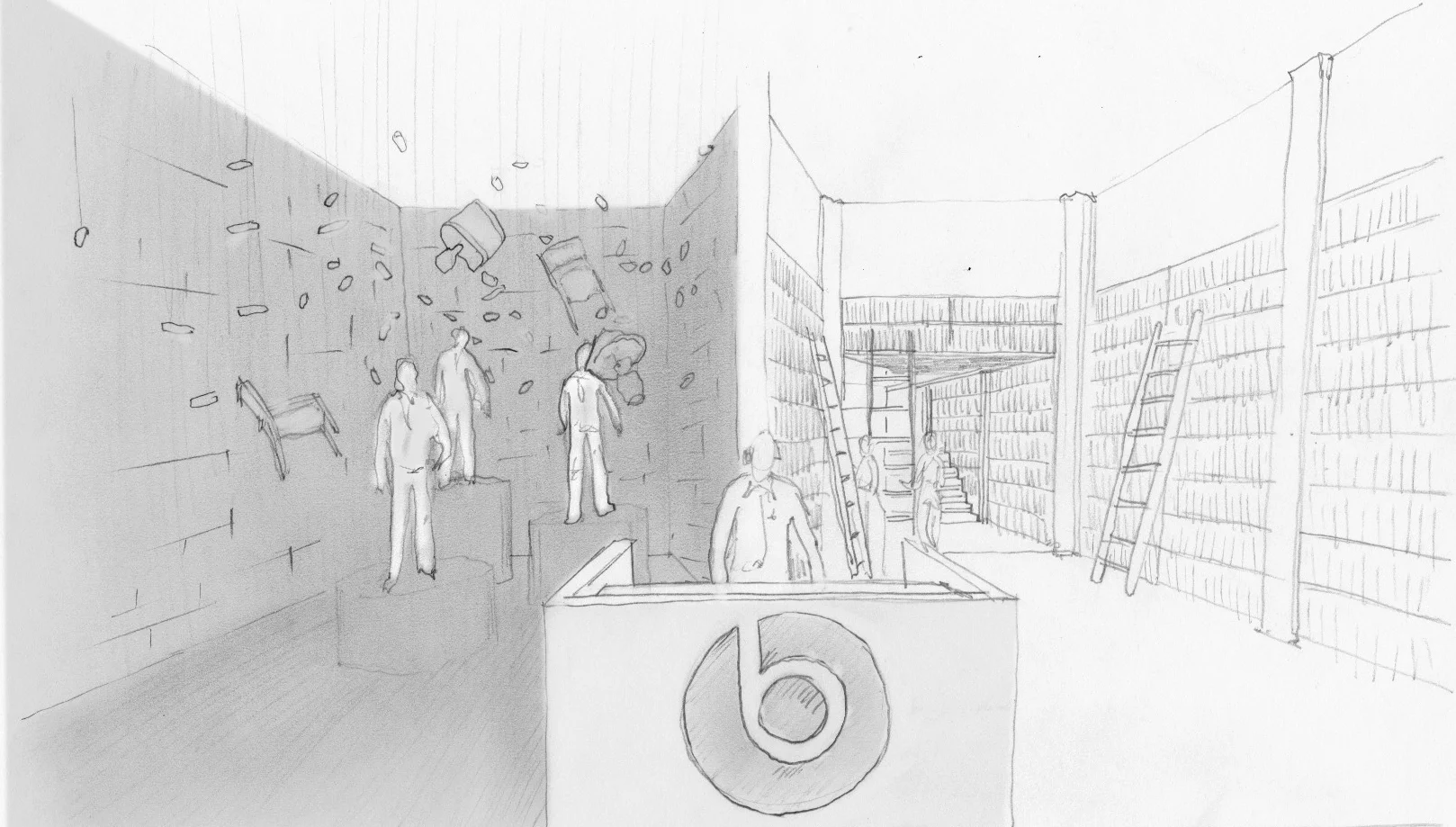

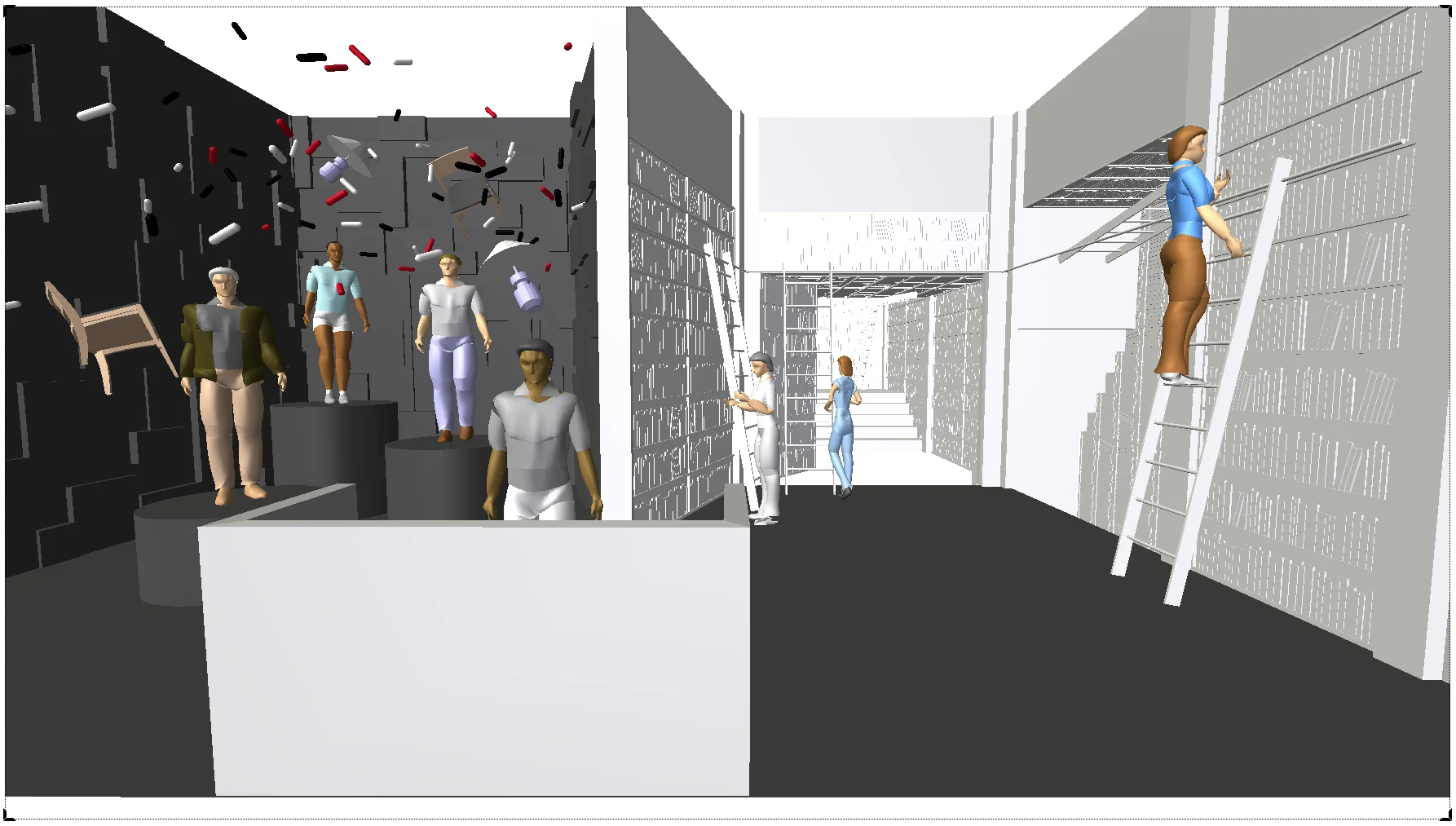

Beats By Dre – a musical party with specifically tailored events for each cewebrity, where throughout the day an artist and his team painted the set with color. These wall pieces were inspired by an Escher-esque library and were made dimensionally using CAD/CAM. A DJ was placed in the center of the “black” world and the “white” world, which by the end, were brought together by color and music.

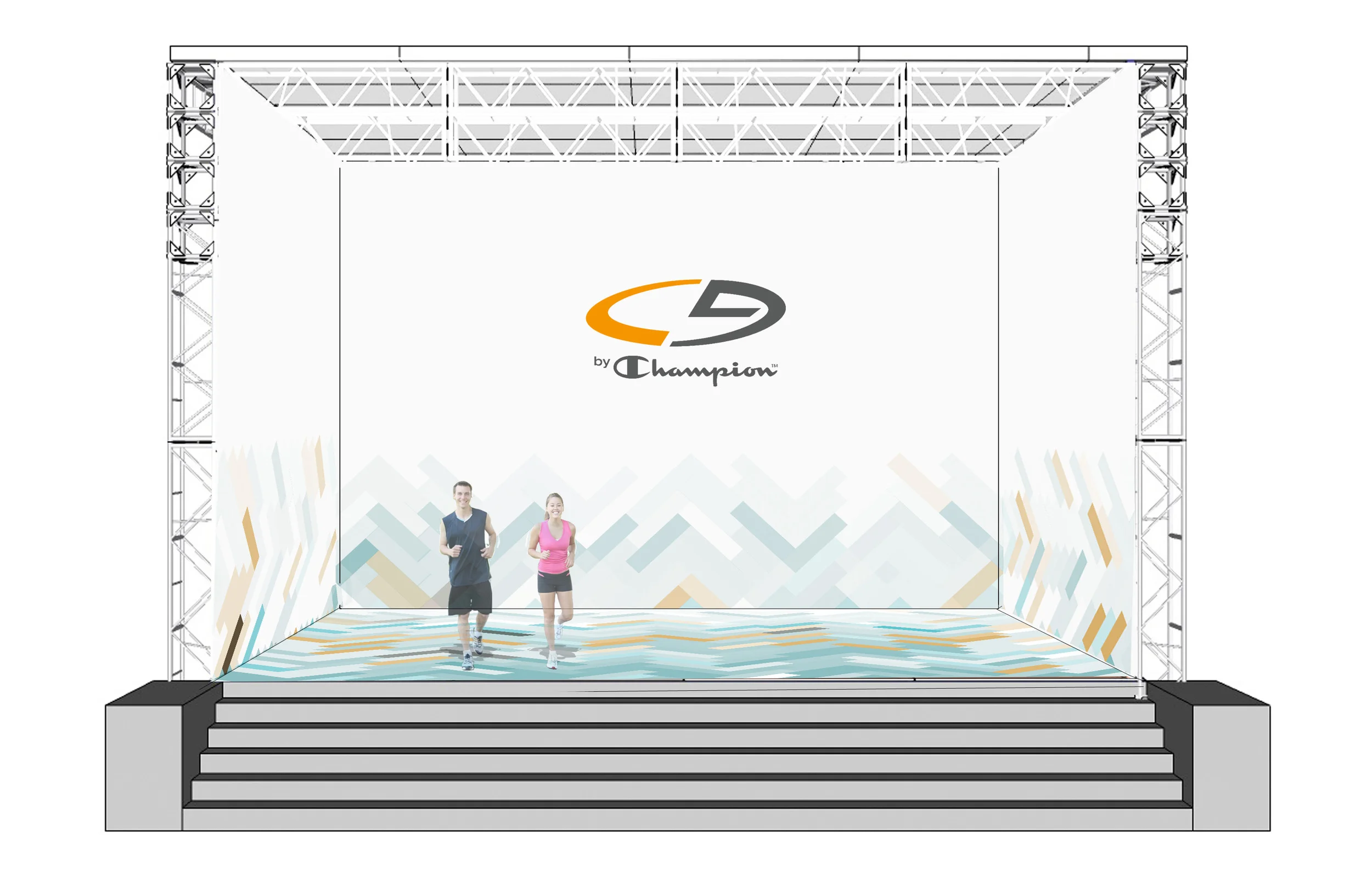

C-9 Lounge – focusing on the activities that utilize Target’s C-9 private label of Champion’s athletic wear, with events from Yoga, capoeira, Surfset and hula hoop to karate, aerial silks, and gladiator jousting! All ending in an MTV Concert!

All in all, this project was a 3 month trial of wits, which brought challenge after challenge, and in the end, was a super success for Target and their partners, as well as for Deutsch LA while going off without a hitch, satisfied clients throughout, and with a perfect safety record.